The drinking water treatment industry is experiencing unprecedented innovation as utilities and technology companies develop cutting-edge solutions to address emerging contaminants, regulatory requirements, and sustainability challenges. From advanced oxidation processes to smart monitoring systems, these innovative technologies are transforming how we produce safe, reliable drinking water for communities worldwide. This comprehensive overview explores the latest breakthroughs in drinking water treatment technology and their practical applications for water treatment professionals.

The Evolution of Drinking Water Treatment

Traditional drinking water treatment has relied on conventional processes like coagulation, flocculation, sedimentation, and chlorination for over a century. While these methods remain effective for many applications, emerging challenges require innovative approaches. Pharmaceuticals and personal care products (PPCPs), per- and polyfluoroalkyl substances (PFAS), and other emerging contaminants cannot be effectively removed by conventional treatment alone.

Water treatment professionals are now integrating advanced technologies that combine multiple treatment mechanisms, utilize artificial intelligence for optimization, and incorporate sustainable design principles to meet both current and future water quality challenges.

Advanced Oxidation Processes (AOPs)

UV/Hydrogen Peroxide Systems

UV/H₂O₂ systems represent one of the most versatile advanced oxidation processes, generating highly reactive hydroxyl radicals (•OH) that can degrade a wide range of organic contaminants including taste and odor compounds, pharmaceuticals, and pesticides.

- Mechanism: UV light (254 nm) photodissociates hydrogen peroxide, producing hydroxyl radicals with oxidation potential of 2.8 V

- Applications: 1,4-dioxane removal, pharmaceutical degradation, taste and odor control, and NDMA precursor destruction

- Design Considerations: UV transmittance requirements (>70%), H₂O₂ dosing systems, and contact time optimization

Operator Tip: Monitor UV transmittance continuously and maintain lamp cleaning schedules. H₂O₂ residuals should be quenched with catalase or allowed to decay naturally to prevent distribution system issues.

Ozonation Enhancement

Modern ozonation systems incorporate advanced control systems, ceramic diffusers, and integrated monitoring to maximize treatment efficiency while minimizing bromate formation and energy consumption.

- Catalytic Ozonation: Uses metal oxides (TiO₂, Al₂O₃) to enhance hydroxyl radical formation and improve micropollutant removal

- Biological Activated Carbon (BAC): Downstream BAC removes biodegradable ozonation byproducts and provides biological stability

- Smart Control Systems: Real-time optimization based on ozone demand, residual monitoring, and water quality parameters

Process Enhancement: Combining ozonation with biological treatment can achieve 90%+ removal of trace organic compounds while maintaining biological stability in distribution systems.

Electrochemical Advanced Oxidation

Electrochemical processes generate oxidants in-situ through water electrolysis, offering precise control and eliminating chemical storage requirements for smaller treatment facilities.

- Boron-Doped Diamond (BDD) Electrodes: Generate hydroxyl radicals directly at the electrode surface with high current efficiency

- Electrochlorination: In-situ chlorine generation from saltwater for remote locations without chemical delivery infrastructure

- Electroflocculation: Simultaneous coagulant generation and flotation for turbidity and color removal

Application Focus: Electrochemical treatment is particularly effective for small to medium-scale facilities requiring minimal operator intervention and reduced chemical handling.

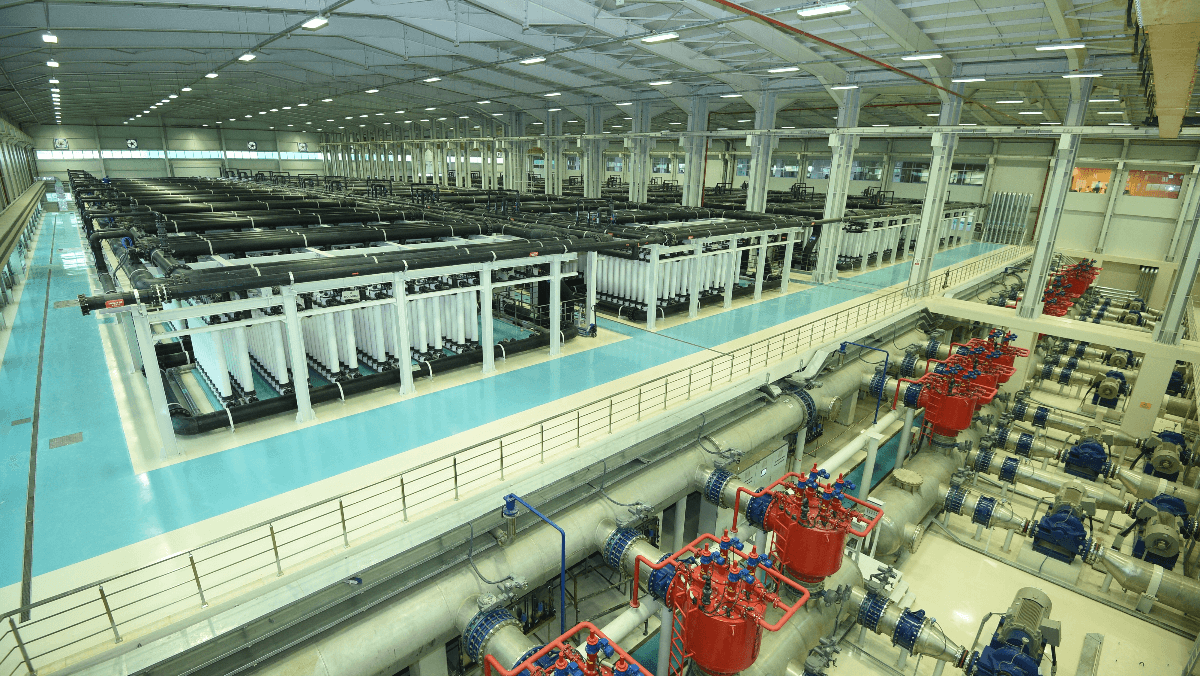

Membrane Technology Innovations

Low-Pressure Reverse Osmosis

Next-generation RO membranes operate at 30-40% lower pressures while maintaining high rejection rates, significantly reducing energy consumption and extending membrane life in drinking water applications.

- Thin-Film Nanocomposite (TFN) Membranes: Incorporate nanoparticles to enhance permeability and rejection of specific contaminants

- Biomimetic Membranes: Aquaporin-based membranes that mimic biological water transport mechanisms

- Forward Osmosis (FO): Uses osmotic pressure differential to reduce energy requirements in brackish water treatment

Energy Savings: Modern low-pressure RO systems can reduce energy consumption by 25-35% compared to conventional membranes while achieving >98% removal of TDS, nitrates, and fluoride.

Ceramic Membrane Technology

Ceramic membranes offer exceptional durability and chemical resistance, making them ideal for challenging raw water conditions and applications requiring aggressive cleaning protocols.

- Material Advantages: Alumina, titania, and silicon carbide membranes withstand pH 1-14 and temperatures up to 400°C

- Backwash Efficiency: High-pressure backwash (up to 5 bar) and air scouring restore flux more effectively than polymer membranes

- Long-Term Performance: Service life exceeding 10 years with minimal flux decline under proper operation

Cost Consideration: While ceramic membranes have higher capital costs, their extended lifespan and reduced replacement frequency often result in lower lifecycle costs for demanding applications.

Smart Water Treatment Systems

Artificial Intelligence and Machine Learning

AI-powered treatment systems continuously analyze multiple data streams to optimize chemical dosing, predict maintenance needs, and ensure consistent water quality while minimizing operational costs.

- Predictive Analytics: Machine learning algorithms predict optimal coagulant doses based on raw water characteristics and historical performance

- Anomaly Detection: Real-time identification of process deviations and equipment failures before they impact water quality

- Energy Optimization: Dynamic adjustment of pump speeds, treatment intensities, and operational schedules based on demand patterns

Advanced Sensor Networks

Multi-parameter sensor platforms provide continuous monitoring of critical water quality parameters with wireless data transmission and cloud-based analytics.

- Optical Sensors: Fluorescence-based detection of organic matter, chlorophyll, and oil contamination with sub-ppb sensitivity

- Electrochemical Arrays: Ion-selective electrodes for real-time monitoring of pH, chloride, fluoride, and heavy metals

- Spectroscopic Analysis: UV-Vis and infrared spectroscopy for continuous monitoring of treatment efficiency and byproduct formation

Implementation Strategy: Start with critical control points (raw water intake, post-filtration, clearwell) and gradually expand sensor networks based on operational priorities and ROI analysis.

Emerging Contaminant Treatment

PFAS Removal Technologies

Per- and polyfluoroalkyl substances (PFAS) require specialized treatment approaches due to their chemical stability and mobility in aqueous systems. Multiple technologies are being deployed at full scale with proven effectiveness.

- Granular Activated Carbon (GAC): Coconut shell-based carbons with optimized pore structures for PFOA/PFOS removal (>90% at 10,000-20,000 BVs)

- Ion Exchange Resins: Strong-base anion exchange resins achieve >95% PFAS removal with regeneration using brine solutions

- Reverse Osmosis: High-rejection membranes remove >99% of PFAS but require concentrate management and disposal strategies

Regulatory Alert: EPA's proposed PFOA/PFOS MCLs of 4 ppt require treatment technologies capable of consistent sub-10 ppt performance with appropriate safety factors and monitoring protocols.

Pharmaceutical and Hormone Removal

Treatment of pharmaceutically active compounds requires multi-barrier approaches combining physical, chemical, and biological treatment mechanisms.

- Powdered Activated Carbon (PAC): Flexible dosing for seasonal pharmaceutical loads with 50-90% removal efficiency for most compounds

- Membrane Bioreactors (MBR): Combination of biodegradation and membrane rejection achieves >80% removal of most pharmaceuticals

- Constructed Treatment Wetlands: Natural attenuation processes for small communities with limited operator resources

Real-World Implementation Case Studies

UV/H₂O₂ for NDMA Control

Orange County Water District implemented UV/H₂O₂ treatment to control NDMA formation in their groundwater replenishment system.

Treatment Results:

95% NDMA removal with 400 mJ/cm² UV dose and 3 mg/L H₂O₂, treating 130 MGD of wastewater for indirect potable reuse with consistent performance over 5+ years.

Ceramic MF for Algae Control

Brisbane Water Board deployed ceramic microfiltration to treat challenging surface water with seasonal algae blooms and high organics.

Performance Data:

Consistent turbidity <0.02 NTU, 4-log virus removal, and >90% TOC reduction with 15-minute backwash cycles and 6-month CIP intervals.

AI-Optimized Coagulation

Singapore's NEWater facilities use machine learning algorithms to optimize chemical dosing across multiple parallel treatment trains.

Operational Benefits:

15% reduction in chemical costs, 25% decrease in filter backwash frequency, and improved treated water quality consistency during raw water variability.

GAC for PFAS Removal

Horsham Water Authority implemented GAC vessels to achieve compliance with Pennsylvania's PFAS action levels of 14 ppt combined PFOA/PFOS.

Treatment Efficacy:

Consistent PFAS levels <2 ppt in treated water with 12,000 bed volumes throughput before breakthrough, using coconut shell GAC with 10-minute EBCT.

Technology Selection and Implementation

- Source Water Characterization:

Comprehensive analysis of raw water quality, seasonal variations, and contaminant profiles guides appropriate technology selection and design parameters.

- Pilot Testing Programs:

Extended pilot studies validate treatment performance, optimize operational parameters, and quantify operational costs before full-scale implementation.

- Regulatory Compliance:

Treatment technologies must meet current and anticipated regulatory requirements while maintaining operational flexibility for changing standards.

- Life-Cycle Cost Analysis:

Comprehensive economic evaluation including capital costs, O&M expenses, energy consumption, and residual management over 20-30 year design life.

Implementation Considerations

- Operator Training Requirements:

Advanced treatment technologies require enhanced operator training, certification updates, and ongoing technical support for optimal performance.

- Infrastructure Integration:

New technologies must integrate seamlessly with existing infrastructure, electrical systems, and SCADA networks with minimal operational disruption.

- Maintenance and Support:

Establish relationships with technology providers for ongoing technical support, spare parts availability, and system upgrades throughout the asset lifecycle.

Frequently Asked Questions

What factors determine the selection of advanced oxidation processes?

AOP selection depends on target contaminants, raw water matrix, treatment objectives, energy costs, and chemical handling capabilities. UV/H₂O₂ works well for broad-spectrum organics, while ozonation excels at taste/odor control and disinfection.

How do ceramic membranes compare to polymer membranes for drinking water treatment?

Ceramic membranes offer superior chemical resistance, longer service life (10+ years), and higher flux recovery, but require higher capital investment. They're ideal for challenging raw water conditions and applications requiring aggressive cleaning.

What are the key considerations for PFAS treatment technology selection?

Technology selection depends on PFAS concentrations, chain lengths, treatment capacity, and concentrate management options. GAC and ion exchange are proven at full scale, while RO requires concentrate treatment or disposal strategies.

How can AI and machine learning improve drinking water treatment operations?

AI systems optimize chemical dosing, predict equipment failures, reduce energy consumption, and maintain consistent water quality. Implementation requires quality data collection, operator training, and integration with existing control systems.

What are the energy implications of innovative treatment technologies?

While some technologies increase energy consumption (UV systems, RO), others reduce overall energy use through process optimization, improved efficiency, and reduced chemical requirements. Life-cycle energy analysis guides sustainable technology selection.

How do innovative technologies address emerging regulatory requirements?

Advanced treatment technologies provide the flexibility to meet evolving regulations for PFAS, pharmaceuticals, and other emerging contaminants. Multi-barrier approaches ensure compliance with current and anticipated future standards.

H2oCareerPro provides comprehensive training and resources for water treatment professionals implementing innovative technologies. Stay current with evolving treatment methods and regulatory requirements to advance your career in water treatment.