Advanced water treatment technologies represent the cutting edge of water purification science, addressing complex contamination challenges that conventional treatment cannot handle effectively. These sophisticated systems combine multiple treatment mechanisms, advanced materials, and intelligent process control to achieve superior water quality while optimizing energy efficiency and operational sustainability. From nanofiltration and membrane bioreactors to advanced oxidation and smart monitoring systems, these technologies are reshaping the water treatment landscape for municipal, industrial, and reuse applications worldwide.

The Scope of Advanced Water Treatment

Advanced water treatment encompasses technologies and processes that go beyond conventional physical, chemical, and biological treatment methods. These systems are designed to remove or destroy contaminants that persist through traditional treatment, including micropollutants, emerging contaminants, and refractory organic compounds. The integration of multiple treatment mechanisms creates robust, multi-barrier approaches that ensure water quality reliability under varying source water conditions.

The advancement of these technologies is driven by increasingly stringent water quality standards, growing concerns about emerging contaminants, water scarcity pressures, and the need for sustainable treatment solutions that minimize environmental impact while maximizing resource recovery and reuse potential.

Membrane-Based Advanced Treatment

Nanofiltration Technology

Nanofiltration (NF) bridges the gap between ultrafiltration and reverse osmosis, selectively removing multivalent ions, organic molecules, and micropollutants while allowing monovalent ions to pass through partially.

- Selective Separation: Molecular weight cutoff (MWCO) of 200-1000 Da enables targeted removal of pesticides, pharmaceuticals, and natural organic matter

- Water Softening: Effective removal of calcium and magnesium while retaining beneficial minerals like sodium and potassium

- Color and Organics Removal: Excellent performance for removing humic and fulvic acids, reducing disinfection byproduct formation potential

Process Advantage: NF membranes operate at 30-50% lower pressure than RO while achieving 85-95% removal of target contaminants, reducing energy consumption and extending membrane life.

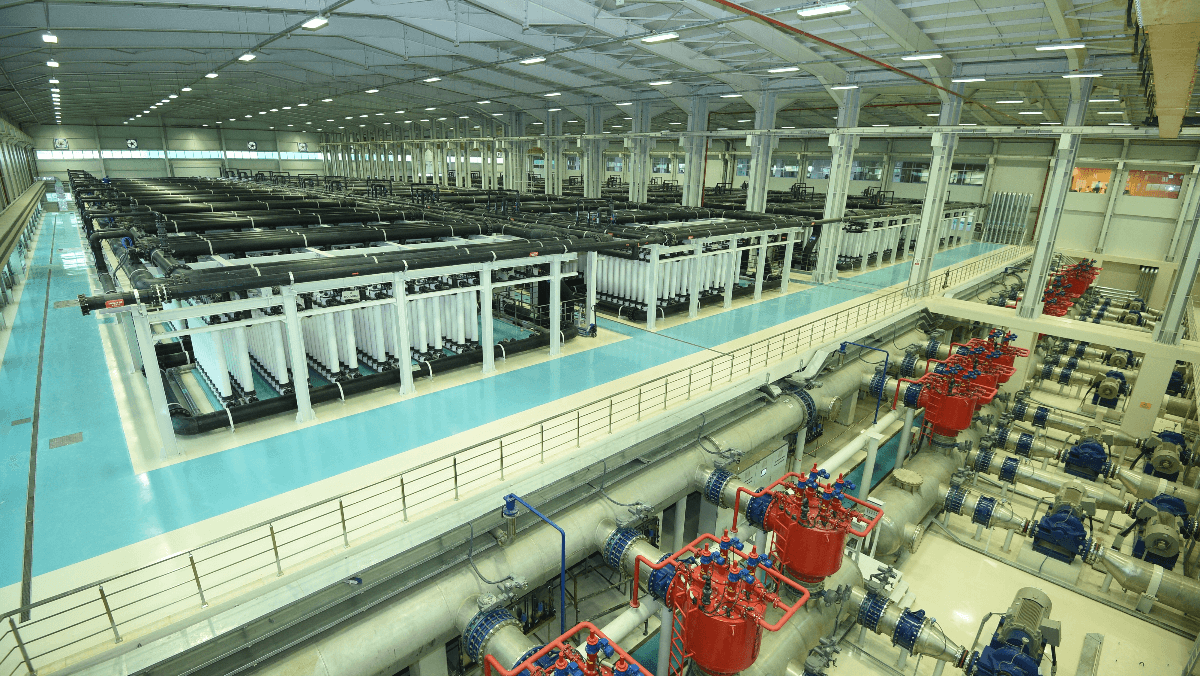

Membrane Bioreactors (MBR)

MBR systems combine activated sludge biological treatment with membrane filtration in a single process, achieving superior effluent quality with reduced footprint compared to conventional treatment trains.

- High-Quality Effluent: Consistent turbidity <0.1 NTU, complete solids separation, and >99% pathogen removal without chemical disinfection

- Process Intensification: Higher mixed liquor suspended solids (8,000-15,000 mg/L) in smaller bioreactor volumes with enhanced treatment efficiency

- Operational Flexibility: Independent control of solids retention time (SRT) and hydraulic retention time (HRT) for optimized biological performance

Water Reuse Applications: MBR technology produces effluent quality suitable for direct potable reuse applications with minimal additional treatment, making it ideal for water-stressed regions.

Forward Osmosis Systems

Forward osmosis (FO) utilizes natural osmotic pressure to drive water transport across semi-permeable membranes, offering energy-efficient treatment for challenging wastewater streams and desalination applications.

- Low Energy Operation: Osmotic pressure differential eliminates high-pressure pumping requirements, reducing energy consumption by 50-70%

- Draw Solution Recovery: Advanced draw solutions with facile separation enable efficient water recovery and draw solution regeneration

- Fouling Resistance: Lower transmembrane pressure and unique flow patterns reduce membrane fouling compared to pressure-driven processes

Emerging Applications: FO technology shows promise for concentrate minimization, industrial water recovery, and emergency water treatment where energy efficiency is critical.

Advanced Biological Treatment

Moving Bed Biofilm Reactors (MBBR)

MBBR technology combines the advantages of suspended growth and attached growth biological treatment using specially designed plastic carriers that provide protected surface area for biofilm development.

- Enhanced Biomass Retention: Biofilm carriers maintain high biomass concentrations (3,000-8,000 mg/L) without sludge recirculation systems

- Process Resilience: Protected biofilm provides resistance to shock loads, toxic substances, and temperature variations

- Retrofit Compatibility: Existing activated sludge tanks can be upgraded with MBBR carriers to increase treatment capacity by 50-100%

Sequencing Batch Reactors (SBR)

SBR systems operate in timed cycles within single reactor vessels, providing excellent process control and treatment flexibility for varying flow and load conditions.

- Cycle Optimization: Programmable fill, react, settle, and decant phases optimize treatment for specific waste characteristics and effluent requirements

- Nutrient Removal: Enhanced biological phosphorus removal (EBPR) and simultaneous nitrification-denitrification in single reactor systems

- Operational Flexibility: Variable cycle times and aeration patterns accommodate diurnal flow variations and seasonal load changes

Small Community Applications: SBR technology is particularly well-suited for small to medium treatment facilities requiring minimal operator attention and robust treatment performance.

Advanced Oxidation and Reduction Processes

Catalytic Ozonation

Catalytic ozonation enhances the efficiency of conventional ozonation by promoting hydroxyl radical formation through heterogeneous catalysis, improving micropollutant degradation and reducing ozone consumption.

- Catalyst Selection: Transition metal oxides (TiO₂, Fe₂O₃, MnO₂) and metal-loaded activated carbon catalysts optimize hydroxyl radical production

- Enhanced Efficiency: 30-50% reduction in ozone consumption for equivalent contaminant removal compared to conventional ozonation

- Bromate Minimization: Catalytic systems reduce bromate formation in bromide-containing waters through selective oxidation pathways

Photo-Fenton Processes

Photo-Fenton systems combine iron catalysis with hydrogen peroxide and UV irradiation to generate hydroxyl radicals for the degradation of persistent organic pollutants and color compounds.

- Solar Applications: Solar-driven Photo-Fenton systems reduce operating costs while achieving >90% removal of pharmaceuticals and industrial chemicals

- Iron Recovery: Advanced systems incorporate iron recovery and recycling to minimize chemical consumption and sludge production

- pH Optimization: Modified Fenton systems operate at neutral pH using chelated iron catalysts, eliminating pH adjustment requirements

Industrial Applications: Photo-Fenton processes excel at treating industrial wastewaters with high organic loads, complex chemical mixtures, and recalcitrant compounds resistant to biological treatment.

Electrochemical Reduction

Electrochemical reduction processes target specific contaminants like nitrates, perchlorates, and halogenated organics through selective electron transfer reactions at cathode surfaces.

- Nitrate Reduction: Catalytic cathodes (Pd-Cu, Pd-Sn) achieve >95% nitrate reduction to nitrogen gas with minimal nitrite formation

- Perchlorate Treatment: Rhenium-based electrodes selectively reduce perchlorate to chloride ions at ambient temperature and pressure

- Dechlorination: Electrochemical dechlorination of PCBs, pesticides, and chlorinated solvents without secondary waste generation

Smart Treatment Systems and Process Control

Digital Twin Technology

Digital twin systems create virtual replicas of water treatment facilities, enabling real-time simulation, predictive modeling, and optimization of treatment processes based on current and historical operational data.

- Process Simulation: High-fidelity models predict treatment performance under varying influent conditions and operational scenarios

- Predictive Maintenance: Equipment performance models identify optimal maintenance schedules and predict component failures before they occur

- Energy Optimization: Dynamic optimization algorithms minimize energy consumption while maintaining treatment objectives and regulatory compliance

Advanced Process Analytics

Multi-parameter online analyzers provide continuous monitoring of critical process parameters, enabling rapid response to changing conditions and automated process control optimization.

- Spectroscopic Monitoring: UV-Vis and fluorescence spectroscopy provide real-time measurement of organics, turbidity, and treatment efficiency

- Biomonitoring Systems: Online respirometry and ATP measurements assess biological activity and optimize biological treatment performance

- Integrated Data Systems: Cloud-based platforms integrate multiple data streams for comprehensive process monitoring and analytics

ROI Benefits: Advanced analytics systems typically achieve 10-20% reduction in chemical costs, 15-30% energy savings, and improved regulatory compliance through consistent performance optimization.

Resource Recovery and Circular Economy

Nutrient Recovery Systems

Advanced treatment systems increasingly incorporate nutrient recovery technologies to capture and recycle valuable phosphorus and nitrogen compounds, creating revenue streams while reducing environmental discharge.

- Struvite Precipitation: Controlled crystallization of magnesium ammonium phosphate (MAP) produces high-quality slow-release fertilizer

- Ammonia Recovery: Air stripping and absorption systems recover ammonia as concentrated ammonium sulfate solutions for fertilizer production

- Membrane Concentration: Forward osmosis and membrane distillation concentrate nutrient streams for efficient recovery and processing

Energy Recovery Integration

Modern advanced treatment facilities integrate multiple energy recovery technologies to achieve net-zero energy operation and reduce operational costs.

- Anaerobic Digestion Optimization: Co-digestion with organic wastes and thermal hydrolysis pretreatment maximize biogas production

- Heat Recovery Systems: Heat exchangers recover thermal energy from effluent streams for heating digester and building systems

- Hydroelectric Generation: Small-scale turbines capture energy from pressure reduction and elevation differences in treatment processes

Sustainability Impact: Integrated resource recovery systems can achieve 40-60% reduction in external energy consumption while generating revenue from recovered nutrients and materials.

Implementation Case Studies

NEWater Singapore MBR-RO

Singapore's NEWater program utilizes MBR-RO treatment trains to produce high-quality reclaimed water for industrial and indirect potable reuse.

System Performance:

Five NEWater plants treat 170 MGD with >99.9% pathogen removal, total organic carbon <0.5 mg/L, and electrical conductivity <100 μS/cm, meeting potable standards.

Orange County GWRS

The Groundwater Replenishment System employs MF-RO-UV/H₂O₂ treatment for indirect potable reuse and seawater intrusion barrier.

Treatment Results:

130 MGD capacity with 6-log virus removal, >99% pharmaceutical removal, and NDMA reduction to <3 ng/L, producing water exceeding drinking water standards.

Perth Groundwater Desalination

Advanced seawater desalination with energy recovery systems and smart monitoring provides climate-independent water supply for Western Australia.

Innovation Features:

100 MGD capacity with energy consumption <3.5 kWh/m³ using pressure exchangers, variable frequency drives, and AI-optimized operation reducing costs by 25%.

Strass Energy-Positive WWTP

Austrian treatment plant achieves energy-positive operation through advanced biological treatment, thermal hydrolysis, and integrated resource recovery.

Sustainability Metrics:

130% energy self-sufficiency, 90% phosphorus recovery as struvite, and 40% reduction in sludge production through process optimization and energy integration.

Technology Selection Framework

- Treatment Objectives:

Define specific removal targets, effluent quality requirements, and regulatory compliance standards to guide technology selection and design criteria.

- Economic Analysis:

Comprehensive life-cycle cost analysis including capital costs, O&M expenses, energy consumption, chemical usage, and potential revenue from resource recovery.

- Site-Specific Factors:

Consider local conditions including available space, energy costs, skilled labor availability, and infrastructure compatibility for optimal technology selection.

- Future Adaptability:

Select technologies with flexibility to accommodate changing regulations, source water quality variations, and capacity expansion requirements.

Future Outlook

Advanced water treatment technologies continue to evolve with increasing integration of artificial intelligence, nanotechnology, and resource recovery systems. The focus is shifting toward circular economy principles, net-zero energy operation, and resilient infrastructure that can adapt to climate change challenges. Water treatment professionals must stay current with these technological advances to design and operate sustainable treatment systems that protect public health while minimizing environmental impact.

Frequently Asked Questions

What are the key advantages of membrane bioreactor technology?

MBR systems provide superior effluent quality, smaller footprint, and operational flexibility compared to conventional treatment. They eliminate secondary clarifiers, achieve consistent turbidity <0.1 NTU, and enable direct biological treatment with membrane separation.

How do advanced oxidation processes compare in terms of energy consumption?

Energy consumption varies significantly: UV/H₂O₂ systems typically require 0.5-2.0 kWh per log reduction, while ozonation needs 8-15 kWh/kg O₃. Catalytic systems can reduce energy requirements by 30-50% compared to conventional AOP configurations.

What factors determine the selection between nanofiltration and reverse osmosis?

Selection depends on target contaminants, energy considerations, and water chemistry. NF excels at removing divalent ions and organics with lower energy consumption, while RO provides comprehensive contaminant removal at higher energy costs.

How can resource recovery technologies improve treatment plant economics?

Resource recovery systems generate revenue through nutrient recovery (struvite, ammonium sulfate), energy production (biogas, hydroelectric), and reduce disposal costs. Combined benefits can offset 20-40% of treatment operating costs.

What are the maintenance requirements for advanced treatment systems?

Advanced systems require specialized training, predictive maintenance programs, and vendor support relationships. Membrane systems need regular cleaning protocols, while AOP systems require UV lamp replacement and catalyst regeneration schedules.

How do digital twin technologies benefit water treatment operations?

Digital twins enable predictive modeling, scenario testing, energy optimization, and predictive maintenance. They provide virtual testing environments for operational changes and help optimize performance while reducing risks and costs.

H2oCareerPro offers comprehensive training and certification programs for advanced water treatment technologies. Enhance your expertise in cutting-edge treatment methods and stay ahead of industry developments.