Artificial intelligence is revolutionizing drinking water treatment operations through intelligent automation, predictive analytics, and real-time optimization systems. From machine learning algorithms that optimize chemical dosing to digital twins that simulate treatment processes, AI technologies are enabling water utilities to achieve unprecedented levels of efficiency, reliability, and sustainability. These advanced systems process vast amounts of operational data to identify patterns, predict equipment failures, and optimize treatment processes in ways that surpass human capabilities, ultimately delivering safer, more cost-effective water treatment solutions.

AI Applications in Water Treatment

Artificial intelligence in water treatment encompasses a broad spectrum of technologies including machine learning, neural networks, expert systems, and predictive analytics. These systems analyze complex datasets from sensors, laboratory results, operational parameters, and historical performance to make intelligent decisions that optimize treatment processes. AI applications range from simple automated dosing adjustments to sophisticated predictive maintenance programs and comprehensive plant optimization systems.

The integration of AI in water treatment represents a paradigm shift from reactive to proactive operation, enabling utilities to anticipate challenges, prevent problems, and continuously optimize performance. This transformation is particularly valuable in addressing the increasing complexity of source water contamination, tightening regulatory requirements, and the need for sustainable, energy-efficient treatment solutions.

Machine Learning for Process Optimization

Intelligent Chemical Dosing

Machine learning algorithms analyze real-time water quality parameters, historical performance data, and environmental conditions to determine optimal chemical dosing strategies for coagulation, pH adjustment, and disinfection processes.

- Multi-Parameter Analysis: Algorithms simultaneously consider turbidity, pH, alkalinity, temperature, flow rate, and seasonal variations to predict optimal doses

- Adaptive Learning: Systems continuously update dosing models based on treatment performance feedback and changing source water characteristics

- Cost Optimization: Algorithms balance treatment effectiveness with chemical costs, achieving 10-25% reduction in chemical consumption without compromising quality

Operational Benefits: AI-controlled dosing systems achieve more consistent treatment performance, reduce chemical waste, and minimize operator intervention while maintaining regulatory compliance across varying conditions.

Filtration Process Control

AI systems optimize filtration operations by predicting filter performance, determining optimal backwash timing, and adjusting operational parameters to maximize filter run times while maintaining effluent quality.

- Breakthrough Prediction: Neural networks analyze turbidity trends, head loss development, and particle counting data to predict filter breakthrough

- Backwash Optimization: Machine learning algorithms determine optimal backwash sequences, duration, and intensity based on filter condition assessment

- Energy Efficiency: AI systems optimize pump speeds, valve positions, and flow distribution to minimize energy consumption while maintaining treatment objectives

Performance Enhancement: AI-optimized filtration systems typically achieve 15-30% longer filter runs, 20-40% reduction in backwash water consumption, and improved effluent quality consistency.

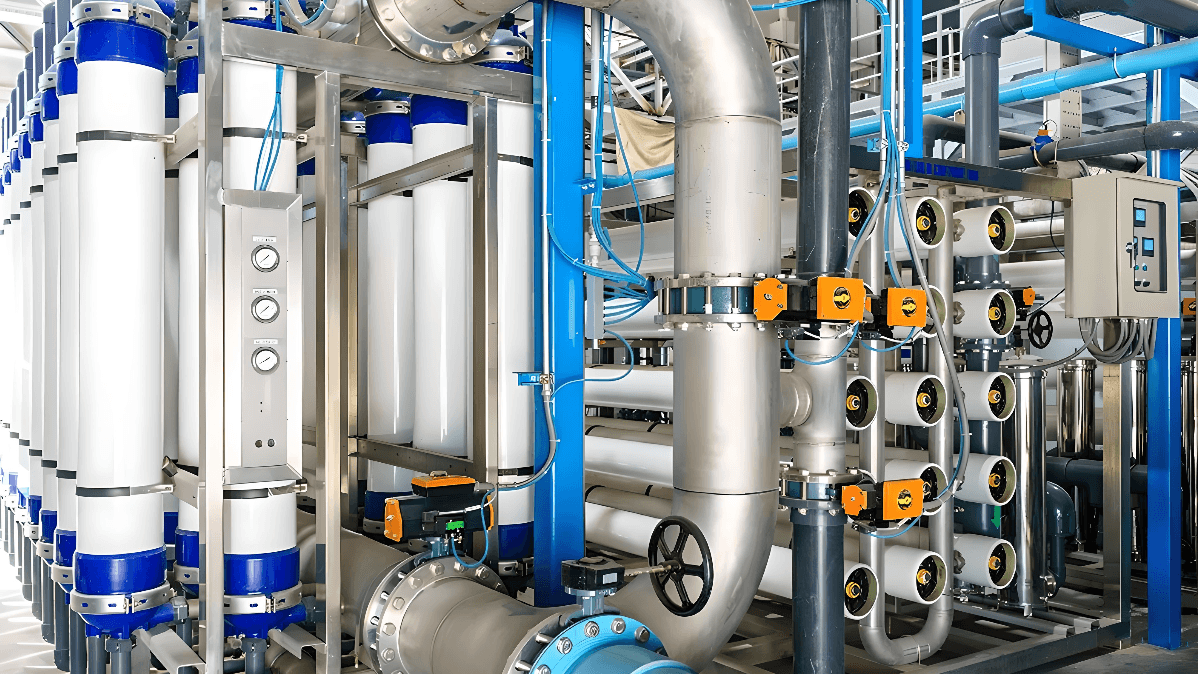

Membrane System Intelligence

Advanced AI algorithms monitor membrane performance, predict fouling patterns, and optimize cleaning protocols to maximize membrane life and maintain consistent permeate quality in reverse osmosis and ultrafiltration systems.

- Fouling Prediction: Machine learning models analyze transmembrane pressure, flux decline, and feed water characteristics to predict membrane fouling

- Cleaning Optimization: AI systems determine optimal cleaning frequency, chemical selection, and cleaning protocols based on fouling type and severity

- Predictive Maintenance: Algorithms predict membrane replacement needs and optimize replacement schedules to minimize system downtime

Economic Impact: AI-managed membrane systems extend membrane life by 20-40%, reduce cleaning chemical consumption by 25-35%, and improve overall system availability through predictive maintenance.

Predictive Analytics and Maintenance

Equipment Health Monitoring

AI-powered monitoring systems continuously assess equipment health using vibration analysis, thermal imaging, electrical signatures, and performance data to predict failures and optimize maintenance schedules.

- Vibration Analysis: Machine learning algorithms detect abnormal vibration patterns in pumps, motors, and blowers indicating bearing wear or misalignment

- Thermal Monitoring: AI systems analyze thermal signatures to identify overheating equipment, electrical faults, and inefficient heat transfer

- Performance Degradation: Algorithms track equipment efficiency metrics and predict when maintenance or replacement will be required

Failure Prevention Systems

Advanced predictive analytics identify potential system failures weeks or months in advance, enabling proactive maintenance that prevents costly equipment failures and treatment disruptions.

- Anomaly Detection: Machine learning models establish baseline performance patterns and alert operators to deviations indicating potential problems

- Root Cause Analysis: AI systems analyze multiple data streams to identify underlying causes of performance issues and recommend corrective actions

- Maintenance Scheduling: Predictive algorithms optimize maintenance schedules based on equipment condition, criticality, and resource availability

Reliability Improvement: Predictive maintenance systems reduce unplanned downtime by 35-45%, extend equipment life by 20-25%, and decrease maintenance costs through optimized scheduling and parts inventory.

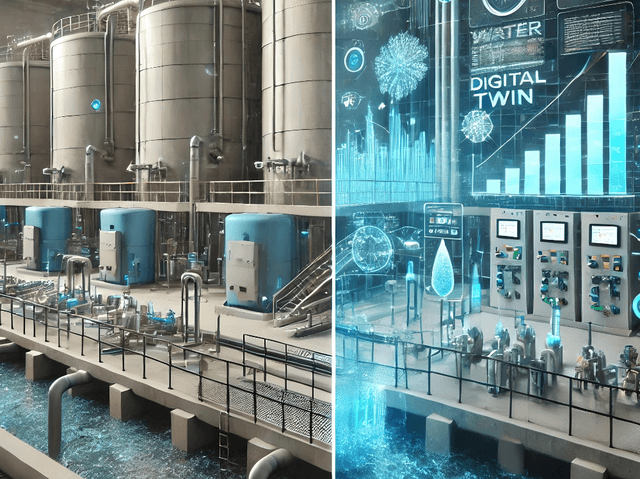

Digital Twin Technology

Virtual Plant Modeling

Digital twin systems create comprehensive virtual replicas of water treatment facilities, enabling real-time simulation, scenario testing, and optimization without disrupting actual plant operations.

- Real-Time Simulation: High-fidelity models mirror actual plant performance using live sensor data and operational parameters

- Scenario Testing: Operators can test different operational strategies, emergency responses, and process modifications in the virtual environment

- Training Platform: Digital twins provide safe training environments for operators to learn complex procedures and emergency responses

Process Optimization

Digital twin systems continuously optimize treatment processes by testing thousands of operational scenarios to identify optimal operating conditions for varying source water quality and treatment objectives.

- Multi-Objective Optimization: Systems balance multiple goals including treatment quality, energy efficiency, chemical costs, and regulatory compliance

- Dynamic Adaptation: Real-time optimization adjusts operations based on changing conditions, demand patterns, and external factors

- Energy Management: AI algorithms optimize energy-intensive processes like pumping, aeration, and UV disinfection based on time-of-use electricity pricing

Performance Gains: Digital twin implementations typically achieve 8-15% energy savings, 12-20% reduction in chemical costs, and improved treatment reliability through optimized operations.

Advanced Sensor Networks and IoT Integration

Intelligent Monitoring Systems

AI-powered sensor networks combine multiple measurement technologies with intelligent data processing to provide comprehensive real-time monitoring of treatment processes and water quality parameters.

- Multi-Parameter Sensors: Advanced sensors simultaneously measure turbidity, chlorine residual, pH, conductivity, and organic matter with AI-enhanced accuracy

- Data Fusion: AI algorithms combine data from multiple sensors to improve measurement accuracy and identify sensor drift or failures

- Edge Computing: Local processing reduces data transmission requirements while enabling real-time decision-making at remote monitoring locations

Smart Alarm Management

AI-enhanced alarm systems reduce alarm fatigue by prioritizing critical alerts, filtering nuisance alarms, and providing intelligent diagnostics to guide operator responses.

- Intelligent Filtering: Machine learning algorithms distinguish between genuine process problems and temporary fluctuations or sensor noise

- Root Cause Identification: AI systems analyze alarm patterns to identify underlying causes and recommend appropriate corrective actions

- Predictive Alerts: Systems generate early warnings for developing problems before they trigger traditional threshold-based alarms

Operator Experience: Intelligent alarm systems reduce alarm volume by 60-80% while improving response times and reducing the risk of missing critical process issues.

Quality Control and Compliance

Automated Quality Assurance

AI systems continuously monitor treatment performance and water quality to ensure regulatory compliance while identifying trends that could impact future compliance.

- Real-Time Compliance Monitoring: Systems track key parameters against regulatory limits and predict potential excursions before they occur

- Trend Analysis: Machine learning algorithms identify long-term trends in water quality that could indicate emerging treatment challenges

- Reporting Automation: AI systems generate comprehensive compliance reports and documentation required by regulatory agencies

Contamination Detection

Advanced AI algorithms rapidly detect contamination events, identify potential sources, and recommend appropriate response measures to protect public health.

- Early Warning Systems: AI monitors multiple water quality parameters to detect contamination events within minutes of occurrence

- Source Identification: Machine learning algorithms analyze contamination patterns to identify potential sources and contamination pathways

- Response Optimization: Systems recommend optimal treatment adjustments, isolation procedures, and emergency response measures

Public Health Protection: AI-powered contamination detection systems can reduce response times from hours to minutes, minimizing public exposure and enabling rapid containment of contamination events.

Implementation Success Stories

Singapore PUB Smart Water Grid

Singapore's national water agency uses AI and IoT sensors across its water network to optimize treatment, detect leaks, and manage water quality.

System Results:

15% reduction in chemical consumption, 25% improvement in energy efficiency, and 40% reduction in response time to water quality events through AI optimization.

Thames Water AI Optimization

Thames Water deployed machine learning systems across multiple treatment plants to optimize chemical dosing and energy consumption.

Performance Improvements:

20% reduction in coagulant consumption, 18% decrease in energy costs, and improved treated water quality consistency across varying source water conditions.

American Water Digital Twin

American Water Services implemented digital twin technology at multiple facilities to optimize operations and train operators.

Operational Benefits:

12% energy savings through process optimization, 30% reduction in operator training time, and improved emergency response capabilities.

Suez AQUADVANCED

Suez's AI platform optimizes treatment processes across hundreds of water treatment facilities worldwide using machine learning algorithms.

Global Impact:

Average 8-12% reduction in chemical costs, 15-20% energy savings, and improved regulatory compliance across diverse geographic and operational conditions.

Implementation Strategy and Best Practices

- Data Infrastructure:

Establish robust data collection, storage, and processing infrastructure with sufficient bandwidth and cybersecurity measures to support AI applications.

- Pilot Testing:

Start with small-scale pilot projects to demonstrate value, build confidence, and develop internal expertise before full-scale implementation.

- Staff Training:

Invest in comprehensive training programs to help operators understand AI systems, interpret recommendations, and maintain appropriate oversight.

- Change Management:

Implement structured change management processes to address operator concerns, build trust in AI recommendations, and ensure successful technology adoption.

Critical Success Factors

- Data Quality:

AI systems require high-quality, consistent data. Invest in sensor calibration, data validation, and quality assurance procedures to ensure reliable AI performance.

- Human-AI Collaboration:

Design systems that enhance rather than replace human expertise, maintaining appropriate operator oversight and decision-making authority.

- Continuous Improvement:

Establish feedback loops to continuously refine AI models, update algorithms based on performance data, and expand applications over time.

Future Developments

The future of AI in water treatment includes advanced applications such as autonomous treatment plants, quantum computing for complex optimization problems, and AI-driven materials discovery for new treatment technologies. As these systems become more sophisticated, they will enable unprecedented levels of efficiency, sustainability, and reliability in water treatment operations while reducing the environmental footprint of water infrastructure.

Frequently Asked Questions

How does AI improve chemical dosing accuracy compared to traditional control systems?

AI systems analyze multiple variables simultaneously and learn from historical performance to predict optimal doses. This typically achieves 15-25% improvement in dosing accuracy, reduces chemical waste, and maintains more consistent treatment performance across varying source water conditions.

What are the cybersecurity considerations for AI-powered water treatment systems?

AI systems require robust cybersecurity measures including network segmentation, encryption, access controls, and regular security audits. Critical systems should maintain manual override capabilities and implement defense-in-depth strategies to protect against cyber threats.

How do digital twin systems help with operator training and emergency preparedness?

Digital twins provide safe training environments where operators can practice complex procedures, test emergency responses, and learn new systems without risking actual plant operations. This accelerates training and improves emergency response capabilities.

What data requirements are necessary for successful AI implementation?

AI systems require consistent, high-quality data from multiple sources including process sensors, laboratory results, and operational records. Typically 1-2 years of historical data is needed for model training, with ongoing data collection for continuous learning and model refinement.

How can smaller utilities implement AI technologies with limited resources?

Smaller utilities can start with cloud-based AI services, focus on specific applications like chemical dosing optimization, partner with technology vendors for managed services, or collaborate with other utilities to share costs and expertise.

What is the typical return on investment for AI implementation in water treatment?

ROI varies by application but typically ranges from 2-5 years. Benefits include reduced chemical and energy costs (10-25% savings), improved efficiency, reduced maintenance costs, and enhanced regulatory compliance. Digital twin systems often show ROI within 18-36 months.

H2oCareerPro offers specialized training programs in AI applications for water treatment, helping professionals understand and implement these advanced technologies. Stay ahead of the digital transformation in water treatment with comprehensive AI education and certification programs.