Introduction: Smarter, Adaptive Water Treatment

Imagine a world where water treatment isn't just about ticking regulatory boxes but is an agile, responsive process that adapts in real time to our communities' needs and the environment's challenges. With cities expanding and climate change throwing new variables into the mix, providing clean, safe water has never been more critical—or more complex. We're up against aging infrastructure, tighter environmental rules, growing populations, and water scarcity that's putting serious strain on utilities. The old methods we've relied on, along with the statement "well, we've always done it that way," are no longer sufficient. They're just not keeping pace anymore.

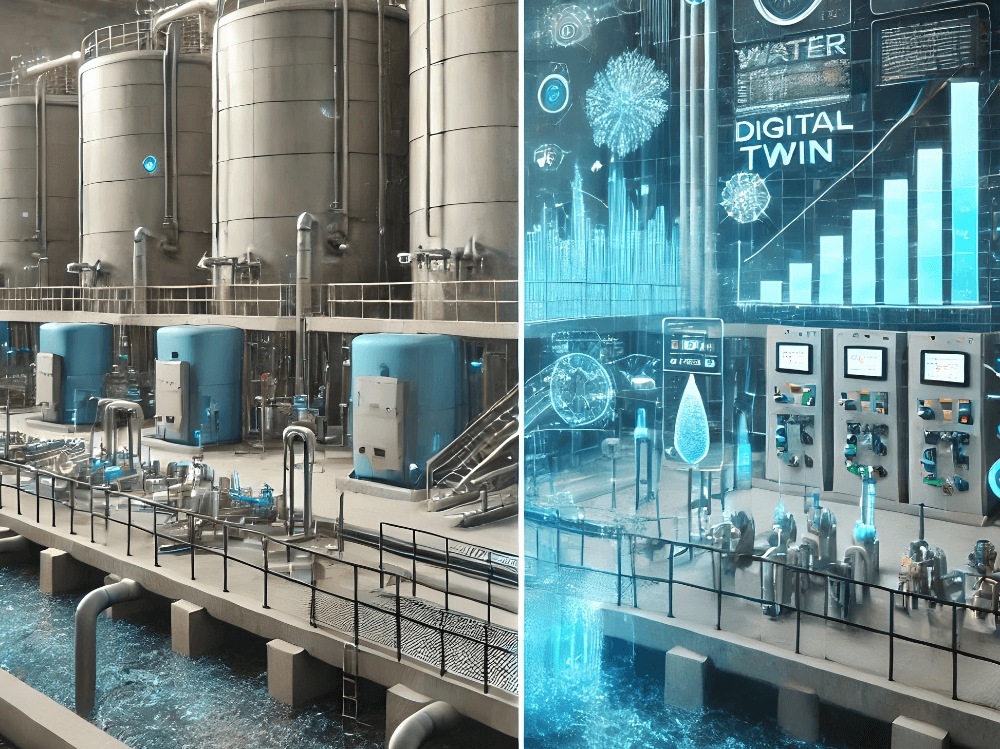

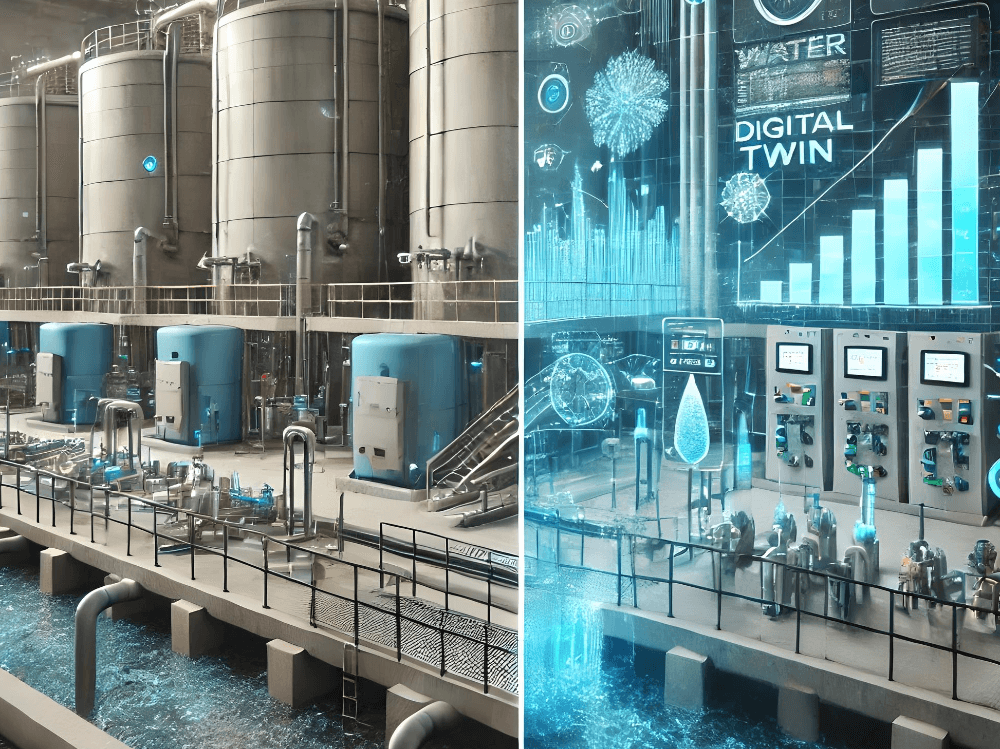

So, what's the game-changer? Enter advanced technologies like Artificial Intelligence (AI) and Digital Twins (DTs). These aren't just tech buzzwords—they're tools that are fundamentally transforming how we treat and distribute water. AI offers predictive insights and real-time optimization, empowering operators to stay ahead of potential issues. Imagine predicting equipment failures before they happen or fine-tuning chemical dosing on the fly to match changing water quality. Plus, by boosting energy efficiency, we're not only cutting costs but also reducing our environmental footprint.

Digital Twins take innovation a step further. Think of them as virtual replicas of our physical systems, constantly updated with live data from sensors throughout the network. This means operators can simulate different scenarios, explore "what-if" situations, and spot potential problems before they escalate, all without touching the actual equipment. It's like having a virtual sandbox to test and refine strategies, leading to smarter, data-driven decisions.

Now, when you combine AI and Digital Twins, the possibilities really start to expand. This dynamic duo creates adaptive systems that learn and evolve, opening up new avenues for transforming water management. We're talking about reduced operational costs, minimized downtime, and more sustainable practices. Things like cutting back on chemical usage and conserving energy. Even the complex maze of regulatory compliance becomes a more streamlined process, if you dare to believe it.

In this report, we'll delve into how AI and Digital Twins are reshaping the water treatment landscape. We'll share real-world success stories, discuss the benefits and challenges, and offer strategies to overcome obstacles like tight budgets, organizational resistance, and cybersecurity concerns. Our goal is to inspire you to embrace these technologies and be part of this exciting evolution toward smarter, more sustainable water management.

The Concept of Digital Twins in Water Treatment

What is a Digital Twin?

Simply put, it's a virtual model that is a mirror image of a physical system—in this case, your water treatment plant or distribution network. This isn't a static snapshot; it's continuously updated with real-time data from sensors, meters, and other IoT devices scattered throughout your operations. Originally used in manufacturing to fine-tune production processes, Digital Twins (DTs) have crossed over into industries like energy, healthcare, and yes, water management.

In the context of water treatment, a DT gives you a high-fidelity virtual representation of your plant's operations, equipment behavior, and distribution networks. This digital mirror lets you monitor everything in real time and even predict what's coming down the pike. You can anticipate potential failures, optimize processes, and implement solutions before small issues become big headaches. It's a simulation that gives you the ability to look into the future of your digital replica, allowing you to stay one step ahead and always prepared.

With the challenges utilities face—such as aging infrastructure, climate variability, and stricter regulations—DTs are invaluable tools. They let you model different scenarios, like spikes in water demand or equipment malfunctions, so you can test solutions virtually without risking actual operations. Plus, the constant feedback loop between your physical systems and their digital counterparts ensures you're always working with up-to-the-minute information, allowing you to adapt swiftly to any changes.

Key Concept: Digital Twins let you model, monitor, and optimize plant operations—turning data into real-time decision power.

Components of a Water Treatment Digital Twin

Real-Time Data Acquisition

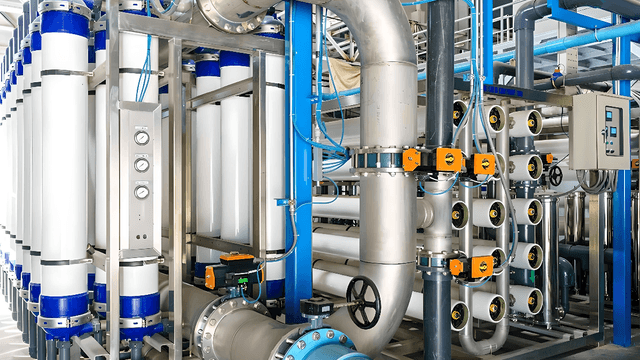

First off, DTs thrive on real-time data. They rely on a robust network of IoT sensors that collect and transmit information on critical water parameters. Metrics like flow rates, pressure, turbidity, pH levels, and chlorine concentrations. These sensors are strategically placed throughout your entire water system, from the treatment plant to the farthest reaches of your distribution pipelines. This comprehensive data collection gives you a holistic view of how your system is performing at any given moment.

High-Fidelity Models

At the heart of a DT are high-fidelity models that replicate the physical processes happening in your water treatment systems. These models take into account fluid dynamics, chemical reactions, equipment behavior, and energy consumption to provide a realistic simulation of plant operations under various conditions. This level of detail lets you conduct in-depth analyses, optimize treatment processes, and predict how different operational strategies will play out. Want to see what happens if you adjust chlorine dosing or test out an emergency shutdown protocol? You can simulate it all without impacting your real-world operations.

AI-Driven Optimization Engines

This is where things get really exciting. By integrating AI algorithms into your DT, you supercharge its capabilities. AI models can detect anomalies, predict equipment failures, and recommend maintenance schedules to prevent costly downtime. By crunching historical data and learning from patterns, these optimization engines can suggest actions to maximize efficiency, reduce chemical and energy use, and ensure you stay compliant with water quality standards.

User Interfaces and Visualization Tools

All this data and modeling wouldn't be much use without intuitive ways to interact with it. DTs come with user-friendly dashboards and visualization tools that present complex data in easily digestible formats—graphs, heatmaps, 3D models, you name it. These interfaces let you monitor key metrics and spot trends at a glance. Plus, they allow you to experiment virtually, testing different treatment scenarios and system settings before making any real-world changes. This not only reduces the risk of operational hiccups but also streamlines decision-making.

Integration with Other Systems

Last but not least, a well-implemented DT plays nicely with your other digital systems, like SCADA (Supervisory Control and Data Acquisition) and AMI (Advanced Metering Infrastructure). By integrating data from multiple sources into a unified model, you get improved visibility across your entire water network—from the treatment plant right to the customer's tap. This holistic approach enhances proactive management and boosts service reliability.

Operator's Tip: Real-time data and simulation let you experiment safely—find bottlenecks and test fixes before making changes in the field.

Digital Twins bridge the gap between your physical infrastructure and digital analysis. They enable you to make data-driven decisions that promote continuous improvement. By leveraging real-time data, advanced simulations, and AI-powered insights, DTs help you anticipate and mitigate risks, optimize processes, and enhance system resilience. Implementing a DT transforms how your water treatment facility operates, paving the way for sustainable, cost-efficient, and compliant water services.

Machine Learning-Enhanced Digital Twins (MLDTs)

Defining ML-Based Digital Twins

Let's talk about taking Digital Twins to the next level by infusing them with Machine Learning (ML). Machine Learning-Based Digital Twins (MLDTs) aren't your standard virtual models, they're dynamic systems that learn and adapt over time. Yes, believe it or not, they can actually learn. Unlike traditional DTs that might rely on set rules or historical data, MLDTs continuously learn from both past and real-time data streams. They adjust to environmental changes on the fly, recognize patterns, predict future trends, and optimize operations in ways manual methods just can't match.

By using AI algorithms, MLDTs excel at tasks like predictive maintenance, process optimization, resource management, and most of all anomaly detection. One of their standout features is their ability to evolve. As new data comes in from sensors across your water network, the models update themselves, refining their predictions and recommendations. This adaptability ensures that your MLDT remains accurate and relevant, even as conditions within your water treatment environment change.

These advanced models leverage cutting-edge machine learning techniques, like artificial neural networks and graph convolutional networks, to analyze complex datasets, spot hidden patterns, and provide actionable insights. For utilities aiming to boost operational efficiency and sustainability while cutting risks and costs, MLDTs are becoming indispensable tools.

Key Concept: MLDTs aren't just digital twins—they learn, adapt, and get smarter as your system and data evolve.

Applications of MLDTs in Water Management

Predictive Maintenance

One of the biggest wins with MLDTs is in predictive maintenance. Traditionally, maintenance schedules are either set at fixed intervals or are "run-to-fail", meaning you fix things when they break. This can lead to unnecessary downtime or emergency repairs that cost a bundle. MLDTs change the game by monitoring equipment like pumps, valves, and pipelines in real time. Using AI algorithms, they predict failures before they happen by analyzing data like vibration levels, pressure readings, and flow rates. This lets you schedule maintenance proactively, avoiding unexpected breakdowns and optimizing the lifespan of your assets.

Operator's Tip: Predictive maintenance with MLDTs means fewer surprises—use data to plan, not just react.

Leak Detection and Localization

Leaks in large water distribution networks can be a major headache, leading to significant water loss and inefficiencies. MLDTs tackle this problem head-on by using advanced neural networks, like Graph Convolution Networks, to detect and pinpoint leaks with high precision. They can process data from multiple nodes at once, even if sensor coverage is spotty. By analyzing factors like pressure drops and flow rate anomalies, MLDTs help you quickly identify and address leaks, reducing water waste and improving overall system performance.

Water Quality Prediction and Optimization

Maintaining top-notch water quality is our primary goal, and MLDTs can make a real difference here. These models simulate various scenarios for things like chlorine dosing, aiming to balance effective disinfection with minimal chemical use. By analyzing real-time data on pH, turbidity, and residual chlorine levels, MLDTs can recommend precise adjustments to your treatment processes. If water quality fluctuates, the system can instantly tweak chlorine dosing at multiple points in your network to meet water quality guidelines, while avoiding excessive chemical use that could lead to disinfection by-products. Once again MLDTs show value by ensuring compliance and cutting operational costs.

Key Concept: MLDTs help maintain water quality by adjusting dosing and predicting changes before they cause issues.

Anomaly Detection and Process Optimization

Preventative maintenance and water quality aren't the only areas that can benefit from MLDTs. They are great at spotting anomalies in system performance. By continuously monitoring data and comparing it to expected values, these models can flag unusual patterns that might indicate equipment issues, inefficiencies, or external disruptions. Real-time alerts enable you to tackle problems before they escalate. Plus, MLDTs help optimize processes by evaluating different operational scenarios to find the most efficient configurations. They might suggest pump schedules that save energy or optimize backwashing cycles to prevent filter clogging.

Operator's Tip: MLDTs can spot the small anomalies you might miss—turn on notifications for real-time alerts and stay ahead of trouble!

The adoption of MLDTs in our sector is a significant step forward for water utilities. By harnessing the predictive power of AI and the adaptability of machine learning, these advanced Digital Twins provide you with the ability to manage water treatment systems more effectively. Their implementation will ultimately reduce costs and enhance service reliability. As the industry evolves, MLDTs will become increasingly essential in tackling challenges like aging infrastructure, regulatory compliance, and resource scarcity.

Case Studies and Success Stories

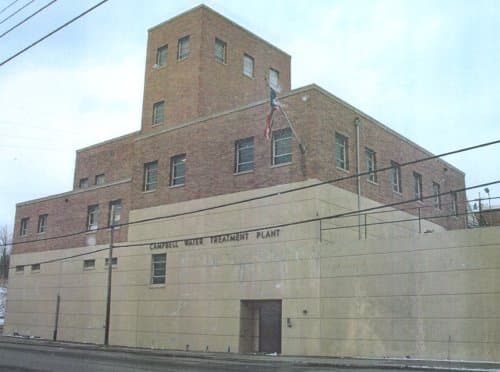

Campbell, Ohio Water Treatment Plant

Let's take a look at a real-world example that illustrates the power of AI in water management. The Campbell, Ohio Water Treatment Plant was struggling with elevated levels of trihalomethanes (THMs), which are harmful by-products formed when organic matter reacts with chlorine. The situation was exacerbated by harmful algal blooms (HABs), a problem that's becoming more common due to climate change and nutrient pollution.

The plant turned to AI-powered software and cloud-based simulation tools to battle these challenges. They developed a dual management strategy that addressed both the impact of HABs and the control of THM levels. This gave operators the ability to simulate various treatment scenarios in real time; allowing them to optimize chemical dosing and resolve operational inefficiencies in a hunt for the most effective method. The final result was the lowest THM levels in the plant's history. This case highlights how AI can empower water treatment facilities to improve water quality, meet regulatory standards, and operate more efficiently…even under tough conditions.

Key Concept: AI and simulation let operators test, optimize, and improve results even in the face of unpredictable challenges.

Digital Twin-Assisted Decision Support in Large-Scale Water Networks

In another great example, a large metropolitan water distribution network implemented a Digital Twin model based on EPANET software. This DT provided operators with unparalleled control over water management. By continuously receiving real-time data, like hydraulic conditions, pressure levels, and chlorine concentrations, the DT enabled dynamic adjustments in chlorine dosing. Operators could optimize chlorine distribution in response to changing demand and water quality, ensuring compliance with safety standards while minimizing chemical use and costs.

But the benefits didn't stop there. The DT also played a crucial role in leak detection. Advanced algorithms processed data from multiple nodes to accurately pinpoint leak locations, even in areas with limited sensor coverage. This significantly reduced water losses and operational inefficiencies. The utility not only saved money but also enhanced the sustainability and reliability of its services, setting a new standard for the use of Digital Twins in modern water networks.

Operator's Tip: Use digital twins and real-time data to optimize dosing, spot leaks early, and deliver smarter service across the entire network.

The Future is Smart Water

AI and Digital Twins are not just emerging technologies—they're becoming essential tools for modern water management. By embracing these innovations, water utilities can enhance operational efficiency, reduce costs, improve water quality, and build more resilient systems for the future.

Ready to transform your water treatment operations? The future of smart, sustainable water management starts with embracing AI and Digital Twin technologies today.