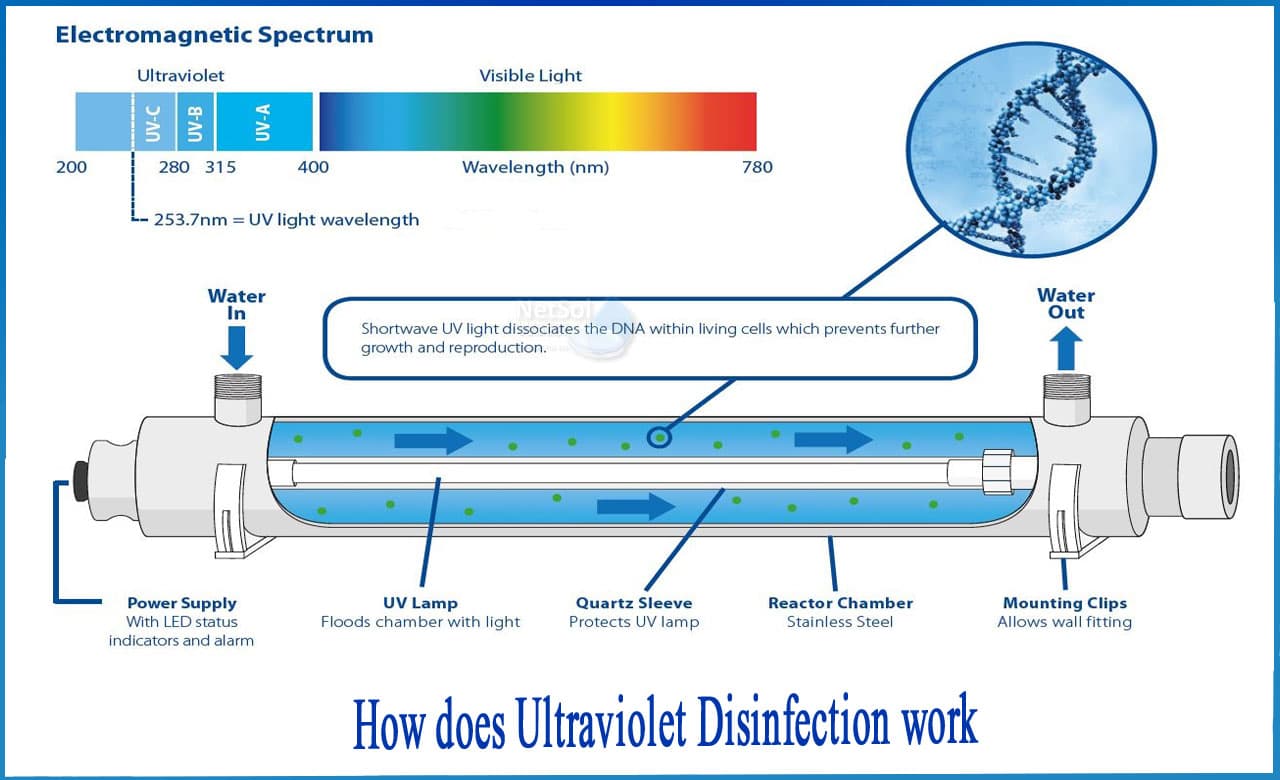

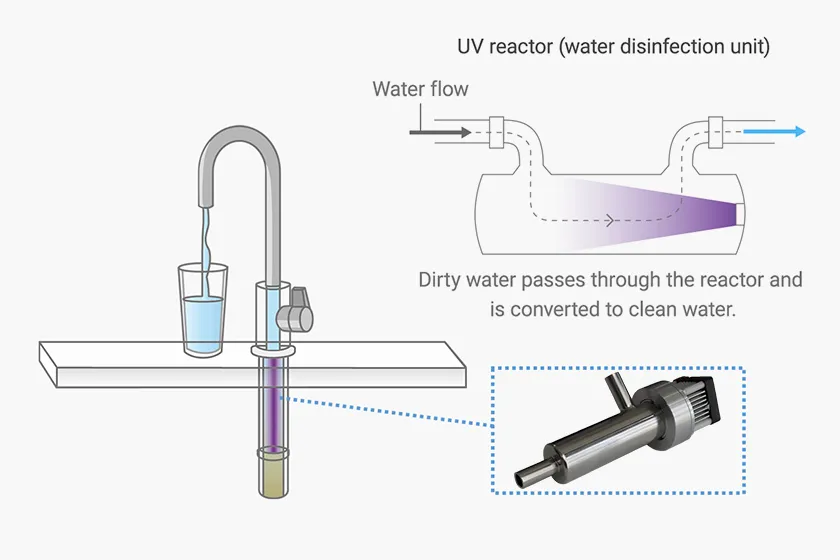

Ultraviolet disinfection has been a backbone technology in drinking water and wastewater treatment for decades. But the industry is rapidly shifting toward UV-LED systems, which are maturing faster than many predicted. Recent advancements now allow UV-LED reactors to achieve 4-log (99.99%) pathogen inactivation while delivering 60-90% energy savings compared to traditional low-pressure mercury lamps.

For water utilities aiming to lower operating costs, reduce maintenance burdens, and meet sustainability goals, UV-LED disinfection is moving from “emerging technology” to practical near-term adoption.

Key Point: UV-LED systems achieve 4-log pathogen removal with 60-90% energy savings over traditional mercury lamps, plus instant on/off capability and mercury-free operation.

Why UV-LEDs Are Advancing So Quickly

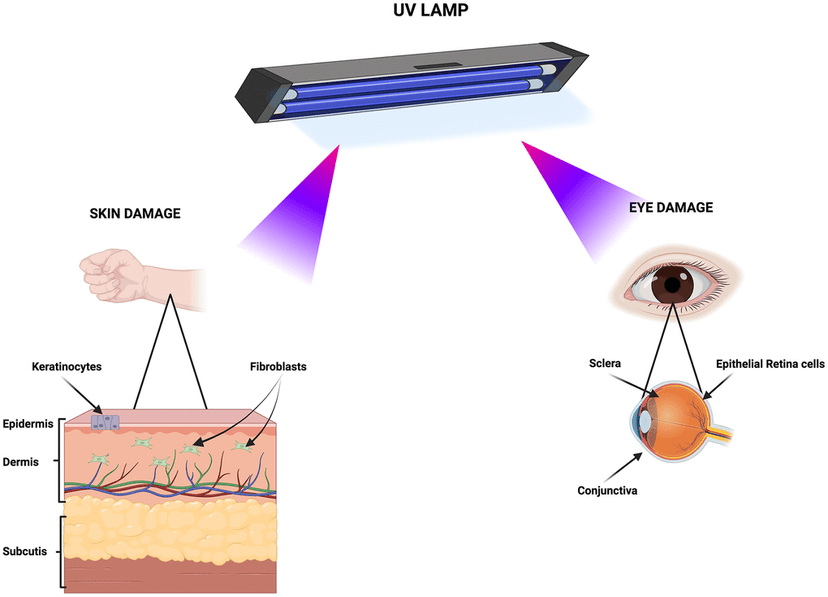

Traditional UV disinfection relies on mercury vapor lamps—effective, but limited by:

- High energy consumption

- Warm-up times and cycling limitations

- Fragile quartz sleeves

- Heat generation

- Mercury handling and end-of-life disposal requirements

LED manufacturers, reactor designers, and water-sector researchers have collectively addressed the early shortcomings of UV-LEDs. Three developments are accelerating adoption:

1. Higher UV Output and Narrow Wavelength Control

UV-C LEDs can now reliably emit in the 260-280 nm range, the most effective germicidal wavelengths. Improved chip design and thermal management have pushed radiant output high enough to support full-scale reactor design—not just point-of-use systems.

2. Dramatically Improved Electrical Efficiency

Next-generation diodes achieve far higher optical output per watt. Combined with instant on/off cycling, utilities avoid the continuous warm-up power draw of mercury lamps. Real-world pilots now consistently show 60-90% lower energy use, especially in systems with variable or intermittent flow.

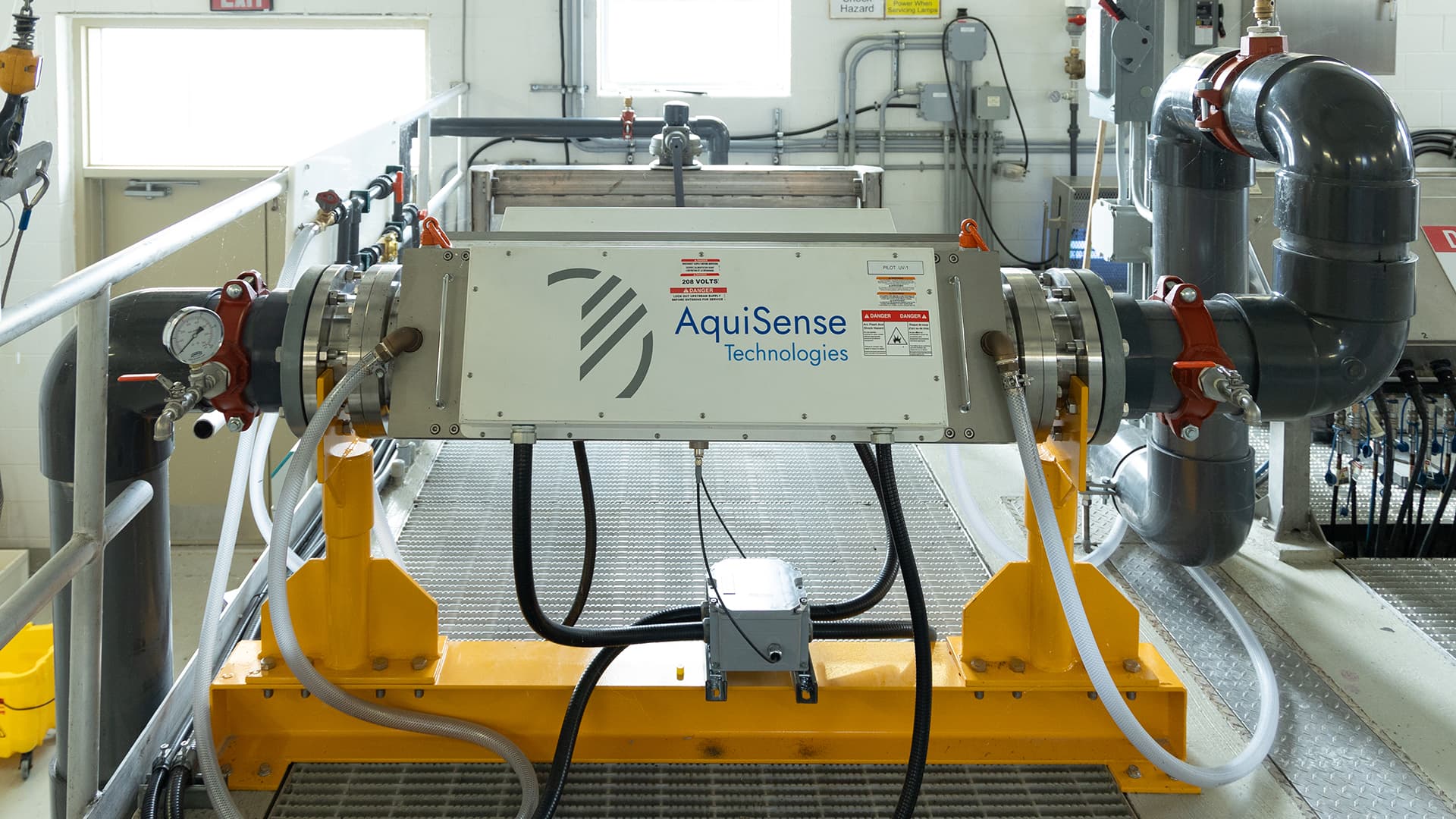

3. Modular, Maintenance-Light Reactor Designs

LED engines last 5-10 times longer than mercury lamps. Since LEDs don't require quartz sleeves, utilities benefit from:

- No fouling-related cleaning

- No sleeve breakage

- No lamp disposal compliance

- Lower downtime and maintenance staffing

Validated Performance: 4-Log Pathogen Removal

Independent studies and pilot installations now demonstrate that UV-LED reactors regularly achieve 4-log inactivation of:

- E. coli

- Cryptosporidium

- Giardia lamblia

- MS2 bacteriophage (commonly used as a UV surrogate)

This performance meets the requirements for many regulated drinking water systems and exceeds what is typically required for decentralized and industrial reuse applications.

Performance Note: Because LEDs respond instantly to flow changes, dose pacing becomes more precise, enabling both energy savings and improved microbial barrier consistency.

Energy Savings Breakdown

Here's where the 60-90% savings come from:

| Efficiency Factor | Impact |

|---|---|

| Instant on/off (no standby power) | Major savings in intermittent systems |

| Higher electro-optical efficiency | Less heat, more UV per watt |

| Targeted wavelength | No wasted energy producing non-germicidal light |

| Smart dose pacing | Automatic dimming at low flows |

| Longer component life | Lower lifecycle costs vs. frequent lamp replacement |

In systems with fluctuating demand—like small drinking water systems, resorts, industrial processes, or potable reuse pilot facilities—actual savings often sit on the high end of the 60-90% range.

Applications Growing the Fastest

Small and Rural Drinking Water Systems

LEDs eliminate the complexity and maintenance challenges of mercury systems—ideal for operators who wear multiple hats.

Advanced Water Reuse (Centralized & Decentralized)

UV-LEDs integrate well with modular reuse skids, point-of-entry systems, and mobile demonstration units.

Industrial Process Water

Instant modulation supports highly variable flows in manufacturing and food/beverage facilities.

Point-of-Use / Point-of-Entry Markets

LEDs enable compact, mercury-free designs tailored to households and commercial buildings.

Regulatory Momentum

While state and federal regulatory frameworks still largely reference mercury-based UV systems, industry groups and manufacturers are actively working with regulators to:

- Develop UV-LED reactor validation standards

- Establish dose-response equivalency testing

- Support LED performance certification under recognized protocols

Several pilot systems in North America, Europe, and Asia are already being used as validation data sources for future regulatory acceptance.

Regulatory Note: Validation protocols for LED reactors are advancing rapidly. Utilities should monitor updates to UV guidance manuals from EPA and state agencies.

What This Means for Water Professionals

The shift to UV-LEDs is not speculative anymore. For many facilities, especially those planning upgrades between now and 2030, LEDs will:

- Lower total lifecycle cost

- Simplify operations and maintenance

- Reduce the facility's environmental footprint

- Eliminate mercury handling and disposal

Action Item: Utilities evaluating treatment upgrades should begin including UV-LED options in feasibility studies, cost comparisons, and pilot testing.

Looking Ahead: What Comes Next

Over the next 3-5 years, expect rapid advancements in:

- Higher power-density LEDs reducing reactor footprint

- Smart, networked reactors integrated with SCADA systems

- Automated dose pacing algorithms leveraging real-time UVT/flow data

- Regulatory validation pathways aligned with LED-specific characteristics

- Further efficiency gains, pushing savings above 90% in some applications

As these components mature, UV-LEDs will increasingly become a default disinfection technology rather than an alternative.

Conclusion

UV-LED disinfection is transitioning from emerging innovation to operational reality—offering 4-log pathogen removal, longer component life, and significant energy and maintenance savings. For drinking water utilities, wastewater treatment operators, engineers, and water industry professionals, this technology represents a major step forward in sustainable, operator-friendly disinfection.